Annealed glass is produced through a meticulous process of slow

cooling, which allows for the release of internal pressure accumulated

during heating. This careful annealing enhances the durability and

overall strength of the glass, making it less likely to crack or

shatter than non-annealed glass. However, while it is stronger than

untreated glass, annealed glass is inherently weaker than tempered

glass.

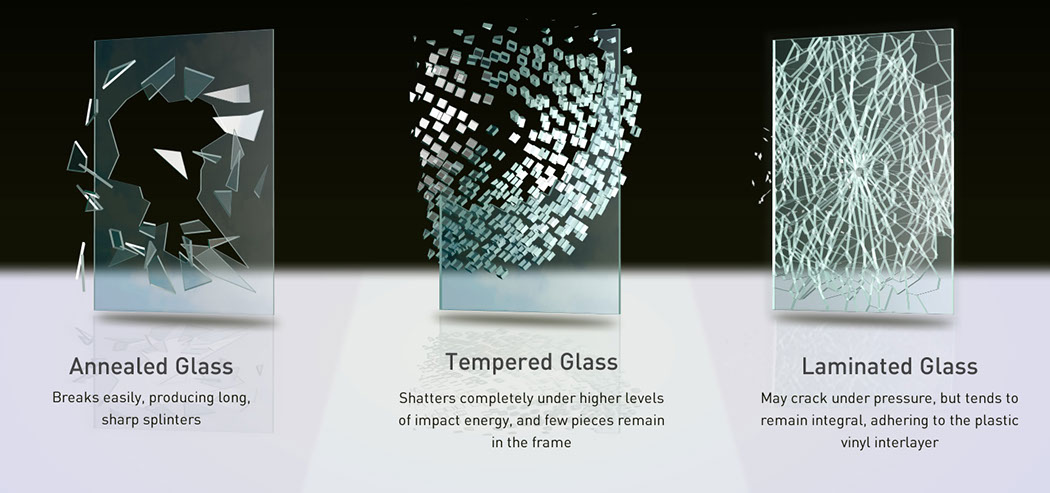

One major difference between the two types is in

their breakage characteristics: tempered glass shatters into smaller,

harmless pieces, while annealed glass breaks into larger, sharper

shards, which can pose a greater risk.

Several features

make annealed glass an ideal choice for specific applications:

Overall, while annealed glass may not have the same resilience as tempered glass, its unique features and cost benefits make it a valuable option in a variety of applications.

Tempered glass, often mistaken for regular glass, is renowned for its exceptional strength. Factors like the heat-treating process and the glass's thickness significantly affect its strength. On average, tempered glass is approximately four times more robust than standard annealed glass. While not entirely unbreakable, it is an excellent choice for safety-conscious applications due to its remarkable resistance to damage. In the event of a break, tempered glass shatters into small, granular pieces instead of large, dangerous shards, minimizing injury risk. It is well-suited for several applications, including storefronts, vehicles, shower enclosures, and diverse industrial uses.

Laminated glass is designed to mitigate or eliminate dangerous shards

during breakage. It consists of at least two layers of annealed or

tempered glass, bonded together by a synthetic material like PVB

(polyvinyl butyrate) or EVA (ethylene-vinyl acetate). This bonding

material helps secure the glass layers together, preventing breakage

and loose shards. Upon impact, laminated glass tends to hold shards in

place and can create a distinctive “spider web” fracture pattern,

absorbing the impact force. Even a basic two-layer laminated glass

piece is stronger than a single layer of annealed or tempered glass.

Manufacturers often enhance their products by incorporating thicker

glass layers or laminating multiple layers together with sheets of

synthetic material between them. The strongest laminates are utilized

in products like bulletproof glass and cockpit windows on commercial

airliners.

While laminated glass offers numerous advantages for

homeowners and business operators, it is notoriously challenging to

cut because it requires penetration of at least two layers of glass

and the synthetic material between them.

Due to its ability to resist catastrophic breakage, laminated glass is a favored choice for various residential and commercial applications. For instance, laminated windows will not crumble when cut from one side, thereby deterring potential burglaries. Additionally, these windows can significantly reduce noise pollution. During severe storms, laminated windows protect your property’s interior from airborne debris and high-speed winds, offering an extra layer of safety against natural disasters like earthquakes, particularly common in the Los Angeles area.

Senior Discount (55+): Present a valid ID for this special discount to be applied. Please note that this offer cannot be combined with other promotions.