The cutting process changes the size or shape of a flat glass sheet, altering its edge from straight to curved. This transformation can be achieved using traditional hand-held tools or modern automated devices, such as water jets and CNC (computer numerical control) machines.

Grooving is used to carve simple or complex patterns into the surface of a glass sheet.

During the drilling process, precisely shaped holes are made in a glass sheet. While hand tools can achieve the necessary accuracy, professionals often prefer machines for consistency and quality control. Countersinking creates a conical hole instead of a straight-sided one.

The bending process involves the controlled application of heat to shape a flat sheet of glass.

Grinding is used to smooth, shape, or polish the edges of a sheet of glass. The process may involve the use of hand tools or machines.

Edges of a glass sheet are shaped into specific decorative profiles.

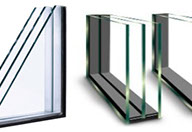

Insulated glass consists of two panes of glass with an airtight space sealed between them. The panes of glass are separated by a spacer material, and the edges are securely sealed to create a single unit. Although spacers are often concealed within the window frame, they play a vital role in the window’s performance. Made of steel, they provide structural integrity and help maintain a seal against thermal and humidity changes. The space between the panes is dehydrated and filled with a safe gas, such as argon or krypton. These gases are denser than air, which helps block heat from passing through the glass. As a result, insulated glass is more effective at reducing heat conduction, thereby improving energy efficiency. Insulated glass improves the window’s overall “u-value,” which measures a building’s heat transmission through windows. The lower the u-value, the better the insulated glass performs. Insulated glass effectively reduces the transfer of heat through it, so your building stays warmer in the winter and cooler in the summer.

Additional techniques used during glass fabrication include engraving, sandblasting, acid etching, satin etching, lamination (the use of multiple, bonded layers of glass to make a single, stronger glass sheet), and tempering (the use of heat or chemical alteration to make a stronger sheet of glass). Advanced fabricators can also perform UV bonding. This modern technique relies on a special ultraviolet light-sensitive adhesive to bond pieces of glass together permanently.

We use the best materials to protect your property

Senior Discount (65+): Present a valid ID for this special discount to be applied. Please note that this offer cannot be combined with other promotions.